Leveraging AI for Enhanced Inventory Management in 2024

Leveraging AI for Enhanced Inventory Management in 2024

As we move further into 2024, the integration of Artificial Intelligence (AI) in inventory management is a necessity for staying competitive. AI transforms how businesses handle inventory, making processes more efficient and decision-making sharper.

AI's role in inventory management is multifaceted. It enhances forecasting, optimizes stock levels, and ensures that businesses can respond quickly to market changes. Moreover, AI's ability to analyze large data sets, identify trends, and predict future demand helps businesses avoid stock shortages and excesses, reducing costs and increasing revenue.

This blog post explores the challenges of inventory management, how AI provides solutions, the latest trends in the field, and practical tips for integrating AI into your inventory management strategy.

Quick Takeaways

- Accurate demand forecasting is critical in inventory management, where inaccuracies can lead to overstocking or understocking, significantly impacting revenues and costs.

- AI significantly improves demand prediction in inventory management, leading to more accurate inventory adjustments.

- By recognizing patterns and trends in extensive datasets, modern forecasting methods surpass traditional limitations and significantly improve demand predictions.

- Businesses benefit from AI's ability to predict and alert them to potential issues like supplier disruptions, aiding in proactive risk management and decision-making.

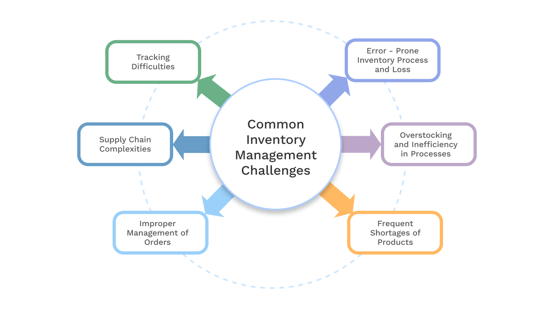

Challenges in Inventory Management

Managing inventory in 2024 presents several challenges that businesses must navigate to stay competitive.

Technological Advancements

Global Supply Chains

Demand Forecasting

According to McKinsey, improving supply chain forecasting accuracy by 10-20% can result in a 5% reduction in inventory costs and a 2-3% increase in revenues. This statistic underscores the significant impact that effective demand forecasting can have on a business's bottom line.

The Role of AI in Overcoming Inventory Management Challenges

Enhanced Forecasting

.png?width=645&height=381&name=Untitled%20(63).png)

For instance, implementing AI in forecasting has been shown to reduce inventory costs by up to 50% while also increasing revenues by improving the accuracy of demand predictions.

Streamlined Supply Chain

Real-Time Inventory Tracking and Management

Emerging Trends in Inventory Management with AI

Omnichannel Inventory Control

- Physical stores

- Online platforms

- Social media

AI plays a critical role in ensuring coordination and visibility across all channels, enabling businesses to move inventory swiftly based on real-time demand. This technology is crucial for tracking inventory levels accurately and enhancing customer satisfaction by reducing the risks of stockouts and overstocking.

Cloud-Based Inventory Management

Warehouse Automation

- Storage

- Picking

- Packing

AI models can determine the most efficient warehouse layout, reducing worker travel time and suggesting optimal product storage locations. The global warehouse automation market is expected to grow at a CAGR of 14.6% between 2023 and 2030, reflecting the increasing adoption of AI in this area.

Risk Management

Practical Tips for Implementing AI in Inventory Management

- Start with Clear Objectives: Define specific goals for your AI implementation, such as improving forecasting accuracy or optimizing warehouse operations. This focus will guide you in selecting appropriate AI tools.

- Choose the Right AI Tools: Select AI tools that specifically meet your inventory management needs, like those with strong predictive analytics for forecasting accuracy.

- Ensure Data Quality: Maintain accurate, comprehensive, and current data for your AI systems, as poor data quality can lead to incorrect AI analyses and decisions.

- Integrate with Existing Systems: Ensure that the AI tools you choose integrate smoothly with your current inventory management systems to enhance processes without disruption.

- Train Your Team: Invest in training and development to equip your workforce with the skills to effectively use AI tools in inventory management.

- Test and Iterate: Begin with a pilot project to test AI implementation, then adjust based on the results for optimal AI system performance.

- Stay Compliant and Secure: Ensure your AI implementation adheres to relevant regulations and prioritize data security to protect sensitive inventory information.

- Measure and Evaluate Performance: Regularly assess the performance of your AI systems against your objectives and use these metrics for continual improvement.

Implementing these tips can help businesses effectively integrate AI into their inventory management processes, leading to improved efficiency, accuracy, and decision-making capabilities.

Embracing the Future of AI in Inventory Management

Hypersonix's advanced solutions, leveraging AI/ML and emerging technologies like IoT, blockchain, and AR, are at the forefront of this transformation. By harnessing the full potential of unified data, Hypersonix is enabling CPG companies to unlock new growth opportunities and drive innovation, ensuring their readiness for the future of an ever-evolving market landscape. Read more about ProfitGPT.

Discover how Hypersonix's AI-driven solutions can revolutionize your pricing approach by scheduling a demo today!