The 1-2-3 Guide to Demand Forecasting

The 1-2-3 Guide to Demand Forecasting

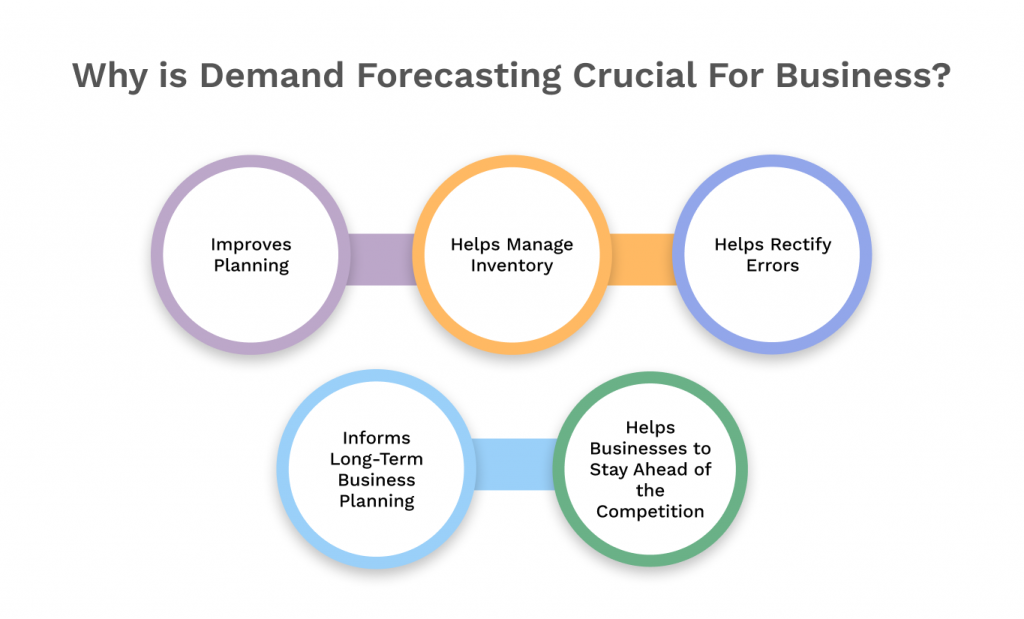

In today’s evolving business landscape, anticipating customer demand is more crucial than ever. Demand forecasting, a systematic approach to predicting future customer needs, has become a cornerstone for businesses aiming to stay ahead of the curve.

According to a recent report by Zion Market Research, the global Demand Planning Solutions Market was valued at approximately $3.62 billion in 2022. This market is projected to reach around USD 8.681 billion by 2030, growing at a compound annual growth rate (CAGR) of about 10.31% from 2023 to 2030.

This surge underscores the increasing reliance of businesses on advanced tools and methodologies to fine-tune their demand predictions.

As we explore the intricacies of demand forecasting and its profound impact on inventory management, we’ll discuss why it’s a game-changer for businesses aiming for profitability, efficiency, and customer satisfaction.

Quick Takeaways

- Demand forecasting uses historical data and market trends to predict future customer needs, influencing business profitability and efficiency.

- Inaccurate forecasting can lead to costly overstocking, brand reputation damage from stockouts, and reactive, inefficient decision-making.

- Inventory management balances stock levels using data analysis and feedback, reducing wastage and ensuring efficient storage use.

- Modern inventory tools enhance demand forecasting with data analytics, seamless software integration, real-time insights, and scenario planning.

Understanding Demand Forecasting

Demand forecasting is the systematic process that businesses employ to anticipate future customer demand for their products or services.

By analyzing historical sales data, market trends, and other relevant factors, companies can make informed predictions about what their customers will want in the future.

Business Impact

- Profitability. Accurate demand forecasting ensures that businesses produce or stock the right amount of products. This means fewer unsold goods, which reduces storage costs and wastage.

- Customer Satisfaction. Meeting customer demand leads to higher satisfaction rates. When customers find what they’re looking for, they’re more likely to return and recommend the business to others. In contrast, stockouts can lead to dissatisfaction and lost trust.

- Operational Efficiency. With accurate demand forecasts, businesses can optimize their operations. This includes better workforce planning, optimized production schedules, and more efficient use of resources. It also allows for better negotiation with suppliers, as businesses can predict their inventory needs more accurately.

Challenges

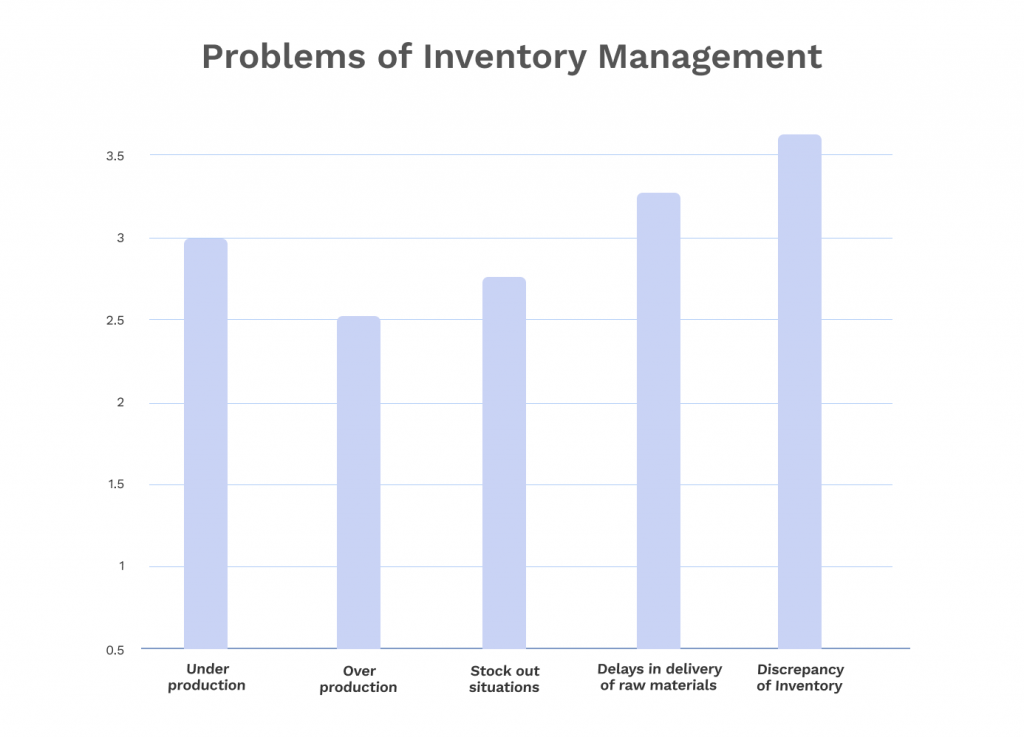

Without proper demand forecasting, businesses face several challenges:

- Overstocking. Holding excess inventory can be costly. It ties up capital, requires storage, and risks obsolescence if products don’t sell.

- Stockouts. Running out of stock can lead to missed sales opportunities and can damage a brand’s reputation. Customers might turn to competitors if they can’t find what they need.

- Reactive decision making. Without forecasting, businesses are always reacting to the market rather than proactively planning for it. This can lead to rushed decisions, inefficiencies, and missed opportunities.

Demand forecasting is a critical strategy that impacts every facet of a business, from finance to operations to customer relations. The ability to anticipate and meet customer demand efficiently can be the difference between business growth and stagnation.

Inventory Management: The Backbone of Effective Demand Forecasting

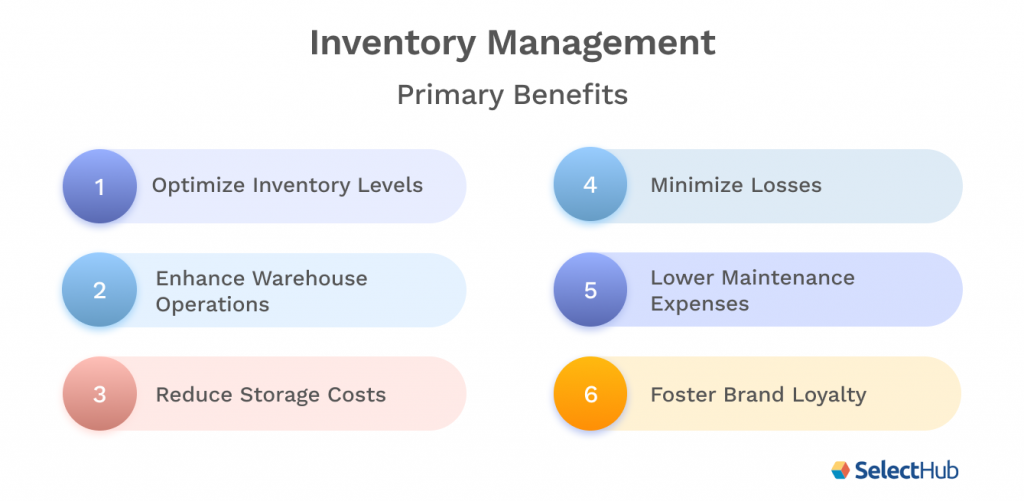

Inventory management is how businesses keep track of their stock. It ensures they have just the right amount of products on hand for their customers, without overspending on excess inventory that might not sell.

Inventory management helps in demand forecasting because it utilizes:

- Data. By watching how fast items sell and when they need restocking, businesses can guess what customers will want next.

- Balance. Good inventory management means not having too much or too little stock. This balance is reached by predicting what customers will buy.

- Feedback. After making predictions, businesses check if they were right. This helps them make better guesses in the future.

Inventory management also solves real-world problems. For one, it reduces wastage, especially for items that can go bad or become outdated. It also prevents money from being tied up in unsold stock, which can strain a business’s finances. And, of course, it ensures that storage spaces are used efficiently, without being overcrowded or too empty.

How Inventory Management Tools Facilitate Demand Forecasting

Inventory management tools offer more than just stock tracking. They provide a multi-faceted approach to understanding and predicting market demand, ensuring businesses are well-equipped to meet their customers’ needs.

Data Collection and Analysis

Inventory management tools are adept at automatically gathering crucial data about sales, stock levels, and returns. This data serves as a foundation for businesses to understand past behaviors and anticipate future trends.

Predictive Power

Approximately 34% of businesses have encountered situations where they have unintentionally sold a product that was unavailable in their inventory. This emphasizes the need for predictive analytics in inventory management.

Many tools come equipped with predictive analytics. They don’t just present data, but rather analyze and interpret it. For instance, recognizing that a product has consistently sold well during certain months can help businesses prepare for similar demand in the upcoming season.

Seamless Integration

These tools often integrate effortlessly with other business software, from accounting systems to eCommerce platforms. This integration provides a comprehensive view, merging sales data with other factors like customer feedback and market trends.

Real-time Insights

A majority of retailers, comprising 72%, plan to transform their supply chain operations by incorporating real-time visibility through automation, sensors, and analytics. This underscores the value of real-time insights in inventory management.

With real-time monitoring capabilities, businesses can instantly see how products are selling. This immediate feedback allows for swift adjustments to forecasts and stock orders, ensuring businesses remain agile in response to market changes.

Scenario Planning for the Future

Scenario planning features enable businesses to test potential future situations. By simulating various “what if” scenarios, businesses can strategize and prepare for different market conditions, ensuring they’re always a step ahead.

Master Demand Forecasting Today with Hypersonix

Demand forecasting, underpinned by robust inventory management, offers businesses the foresight they need to thrive. By leveraging historical data, market trends, and advanced tools, companies can navigate the challenges of overstocking, stockouts, and reactive decision-making.

Inventory management tools, with their multifaceted capabilities, further enhance this predictive power. Companies that harness these tools and strategies position themselves for growth, profitability, and sustained customer satisfaction.

Hypersonix is a profit optimization platform that uses AI-powered tools to help DTC and eCommerce companies excel. Hypersonix’s ProfitGPT inventory management tools can help businesses leverage generative AI and inventory intelligence to provide actionable insights about inventory levels(Inventory AI) and pricing strategies(Pricing AI).

To see how Hypersonix’s AI tools can help automate your pricing strategy, request a demo today!