5 Key Benefits of Integrating Inventory Forecasting Into Your Retail Strategy

5 Key Benefits of Integrating Inventory Forecasting Into Your Retail Strategy

For retailers, accurate inventory management is the linchpin that ensures products are available when customers want them, without tying up unnecessary resources. Enter inventory forecasting: a strategic tool that leverages data to predict demand patterns and optimize stock levels.

This article explores how integrating inventory forecasting into your retail strategy can revolutionize operations, improve efficiency, and drive profitability. Discover the transformative benefits and practical applications of this essential tool, supported by insights into how AI solutions can elevate your retail performance.

Quick Takeaways

- Inventory forecasting predicts consumer demand accurately, minimizing stockouts by aligning inventory levels with market trends and historical data.

- Forecasting ensures optimal stock levels, reducing stockouts to enhance customer satisfaction while minimizing overstock to improve profitability and operational efficiency.

- Effective forecasting aligns inventory with demand, optimizing cash flow by reducing excess inventory and reallocating resources to critical business areas.

- Forecasting optimizes supply chain operations, streamlining logistics, cutting costs, and improving inventory turnover rates to boost overall efficiency and responsiveness.

1. Enhanced Demand Planning

Accurately predicting consumer demand is crucial for retailers aiming to maintain customer satisfaction and maximize revenue.

Inventory forecasting plays a pivotal role in enhancing demand planning by analyzing historical sales data, market trends, and other relevant factors to forecast future demand patterns. According to a study by McKinsey, effective demand forecasting can reduce forecasting errors by up to 50%.

By leveraging advanced predictive analytics, retailers can anticipate fluctuations in consumer preferences and seasonal trends with greater accuracy. This proactive approach allows retailers to align their inventory levels more closely with actual demand, minimizing the risk of stockouts while reducing the need for costly overstocking.

For instance, a clothing retailer can use inventory forecasting to predict spikes in demand for seasonal items or trending fashion styles, ensuring they have the right products in stock at the right times.

2. Reduction in Stockouts and Overstock

One of the most significant challenges in retail inventory management is finding the delicate balance between stockouts and overstock. Stockouts—instances where popular products are unavailable—can lead to lost sales opportunities and dissatisfied customers. On the other hand, overstock ties up capital and valuable storage space, potentially leading to markdowns and reduced profitability.

Inventory forecasting addresses this challenge by providing retailers with insights into future demand trends. By accurately predicting when and how much stock will be needed, retailers can maintain optimal inventory levels. This not only reduces the likelihood of stockouts, but also minimizes overstock situations.

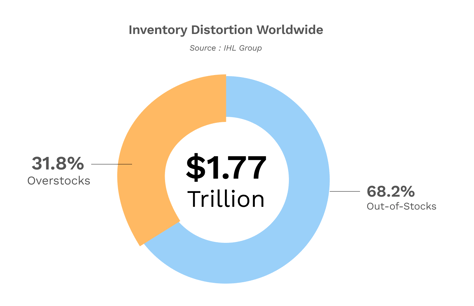

According to recent data, worldwide inventory distortion, which includes stockouts and overstock, cost retailers an estimated $1.77 trillion in 2023.

For example, a grocery chain can use inventory forecasting to adjust their stock levels of perishable goods based on anticipated customer demand, thereby reducing waste and improving profit margins.

3. Improved Cash Flow Management

Effective inventory forecasting significantly enhances cash flow management for retailers by precisely predicting demand and aligning inventory levels accordingly. This strategic approach minimizes the capital tied up in excess inventory, freeing resources that can be reinvested into critical business areas such as marketing campaigns or operational expansions.

According to recent data, poor cash flow management is responsible for 82% of all company failures, highlighting the critical importance of effective financial strategies. Additionally, inadequate cash flow forecasting and financial management cause 80% of unsuccessful enterprises to fail.

For instance, an electronics retailer can use inventory forecasting to anticipate demand for popular gadgets during peak seasons, ensuring optimal stock levels without overcommitting capital. By maintaining leaner inventory levels through accurate forecasting, retailers can improve liquidity and profitability while avoiding unnecessary costs associated with carrying excess stock.

4. Enhanced Operational Efficiency

Operational efficiency is essential for retailers to maintain competitiveness and meet customer expectations.

Inventory forecasting plays a pivotal role in optimizing supply chain operations by providing actionable insights into inventory requirements across various locations and channels. By leveraging precise demand forecasts, retailers can streamline logistics, reduce transportation costs, and enhance inventory turnover rates.

For example, a multinational retailer can use inventory forecasting to coordinate product shipments to regional warehouses based on anticipated demand patterns. This proactive approach:

- Ensures efficient distribution

- Minimizes stockouts

- Optimizes inventory management

By integrating advanced forecasting techniques, retailers can achieve greater efficiency, improve customer service levels, and ultimately drive overall business performance.

5. Competitive Advantage

Inventory forecasting provides retailers with a strategic edge by enabling them to respond swiftly to market changes and consumer trends. By accurately predicting demand and optimizing inventory levels, retailers can offer better product availability and customer service, which enhances overall customer satisfaction and loyalty.

According to Deloitte, retailers will significantly increase data-sharing and collaboration with value chain partners to improve forecasting effectiveness, creating efficiencies along entire supply chains and better anticipating demand for goods. Nearly half of the retailers surveyed identify artificial intelligence as a key tool in automating this process.

Furthermore, inventory forecasting allows retailers to adopt proactive pricing strategies and promotional campaigns based on anticipated demand, optimizing revenue generation opportunities. For example, a retail chain can use inventory forecasting to plan targeted promotions for high-demand items, driving sales and maximizing profitability.

McKinsey highlights that companies integrating AI in their operations have reported enhanced productivity and customer experience, contributing to both top-line and bottom-line growth.

Driving Efficiency and Profitability with Hypersonix Today

Integrating inventory forecasting into retail strategy isn't just about predicting demand—it's about transforming how retailers operate. By leveraging advanced analytics to predict demand patterns accurately, retailers can enhance their ability to meet customer expectations while optimizing operational efficiency and cash flow management.

Explore how Hypersonix’s advanced inventory forecasting solutions can revolutionize your retail operations. Schedule a demo today to see firsthand how our predictive analytics can optimize your inventory management, enhance efficiency, and boost profitability.