Inventory Intelligence: An AI-Driven Category

Inventory Intelligence: An AI-Driven Category

After spending 2021 anxiously awaiting millions of tons of merchandise and materials trapped on cargo ships in deadlocked queues around the globe, retailers face an entirely new problem in 2022– swelling inventories in an economy where purchasing is trending downwards. Between April 2021 and April 2022, U.S. non-auto inventory value ballooned by nearly $100 billion, leaving big box stores and e-commerce pureplays with dwindling profits and rising internal costs while they sat on inventory that was out-of-season by the time it was in-stock. Like last year’s supply chain bottlenecks, the current predicament of the retail industry highlights a glaring lack of inventory intelligence and visibility into increasingly complex global supply chain dynamics.

Most business leaders know they have diminished forecasting ability as a recession looms on the horizon. In 2021, U.S. business logistics expenses rose 22%, accounting for 8% of national economic output and marking the highest single-year increase since the financial crisis of 2008. With geopolitical uncertainties on the rise, businesses can no longer afford to rely on just-in-time inventory practices. So long as the supply chain remains exceedingly vulnerable to unforeseen shocks and disruptions, retailers must rethink supply chain and inventory management.

In this guide, you’ll learn what inventory intelligence is and how artificial intelligence (AI) can radically enhance inventory intelligence in your organization.

Key Takeaways

- Last year’s supply chain disruptions and delays have become this year’s overstocked inventories.

- Traditional inventory management methods such as just-in-time work well in stable, booming economies. In times of high uncertainty and volatility throughout the global supply chain, retailers must look to other methods to mitigate the risks of excess or insufficient inventories.

- Inventory intelligence is a conceptual approach to inventory management that attempts to incorporate all business data into data-backed recommendations. Given the volume of data businesses now create, inventory intelligence must be an AI-driven process.

Inventory Intelligence vs. Just-in-Time Inventory Management

Throughout the last half century, the global supply chain has largely improved year-over-year with incremental developments in efficiency, reliability, and interconnectedness. This period of stable growth in supply chain performance allowed businesses to rely on the concepts of lean manufacturing and just-in-time (JIT) inventory management.

For retailers and e-commerce merchants, JIT inventory means keeping on-hand inventories to a bare minimum necessary to operate. So long as supply and delivery remain dependable, businesses can place orders in the narrowest possible window, reducing storage costs and – where applicable – ensuring the delivery of on-trend products to customers.

Under the right conditions, JIT inventory not only reduces overhead. It also allows businesses to operate efficiently and competitively with rudimentary monitoring of their inventory conditions. In JIT operations, management only needs to define the on-hand minimums that trigger new orders, and optimized order sizes generally reflect recent historical sales data.

However, inventory management radically compounds in complexity when the conditions that enable JIT change and retailers lose the security of a stable supply chain and delivery network. Predictable recurring inventory minimums and product movement no longer suffice to avoid excess or scarcity inventory crises.

Inventory Intelligence

Inventory intelligence refers to the inventory data visibility necessary for businesses to forecast, order, and maintain optimal inventory levels, taking advantage of demand surge opportunities and minimizing excess storage and shipping costs when sales lag. Compared to approaches like JIT, inventory intelligence is holistic rather than minimalist. It means analyzing all available business data to identify patterns and trends and building out strategies and recommendations based on data-backed insights instead of expecting that conditions in the supply chain and the consumer market will remain stable.

Video-Embed: https://www.youtube.com/watch?v=1xO-6VN6mKg

Inventory Intelligence and AI

While the concept of inventory intelligence is relatively simple on the surface, it isn’t very easy to implement in your day-to-day operations without the right tools. As large retailers now capture billions of data points every day, deep data analysis for real-time inventory intelligence is no longer a matter of running a few manual queries and generating a handful of spreadsheets.

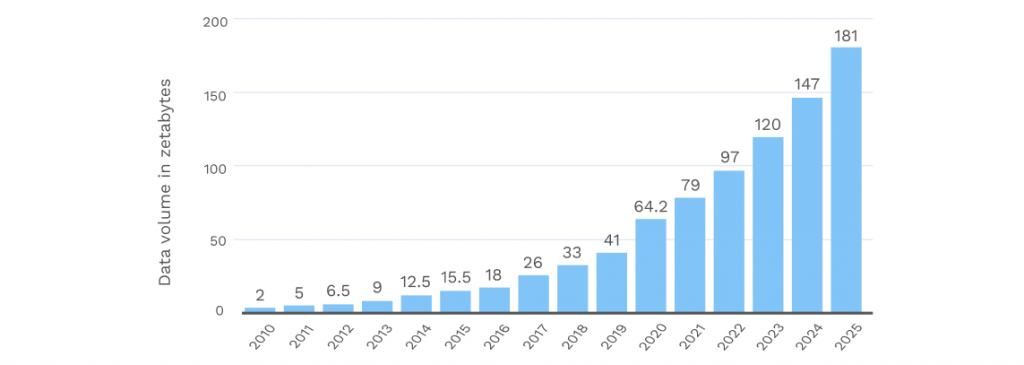

The global datasphere – the total amount of data generated and captured in human activities – has doubled in the last three years, expanding from 41 zettabytes – a number of bytes equal to 1 followed by 21 zeroes – in 2019 to 97 in 2022. It is on pace to double again before 2025. The growth of data captured in business operations reflects this global trend.

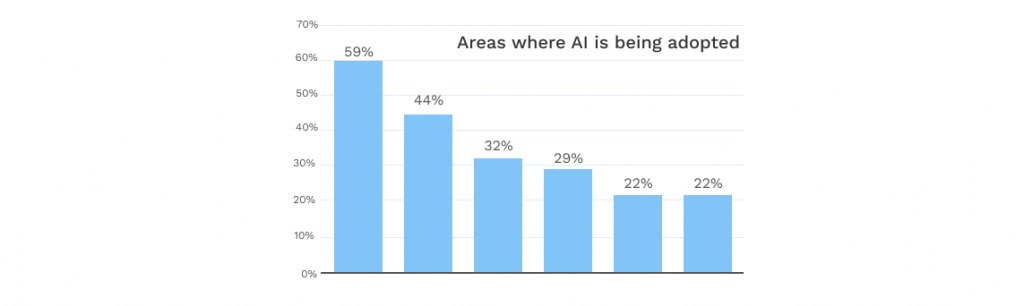

Businesses need to leverage the power and adaptability of AI to make use of volumes of data orders magnitude beyond the scope of manual analysis. Because AI and deep learning algorithms are non-static and capable of generating their own categories and hypotheses with minimal supervision, they far exceed the analytical leverage of simple process automation. With AI, you can transform raw data directly into actionable insights and the rise of inventory management to the second largest AI adoption category in retail businesses reflects a growing understanding of this with regard to inventory challenges

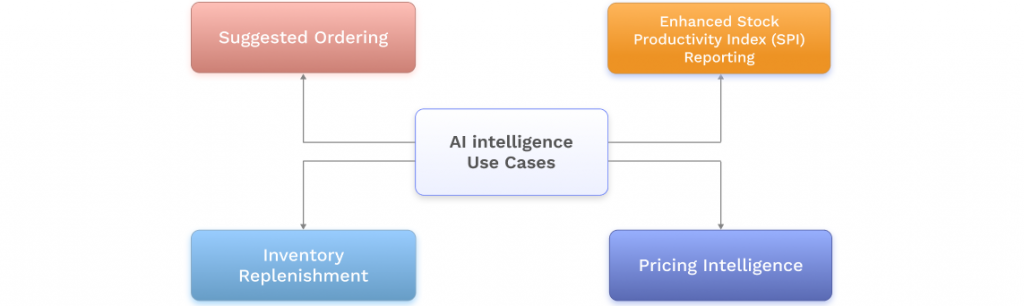

As applied to creating real-time inventory intelligence, AI opens up several distinct possibilities. Here are four types of use cases.

1. Suggested Ordering

With visibility into your ordering data, you can configure various automated processes.

- Match current needs to suppliers’ order minimums

- Populate to-be-ordered lists for editing and purchase review

- Set conditions to bypass manual purchase orders

- Reduce out-of-stocks with automated inventory scarcity monitoring

2. Enhanced Stock Productivity Index (SPI) Reporting

SPI measures how efficiently inventory is moving. Passing your sales data through the right AI, you can extend this capacity significantly.

- Automatically identify poor-performing products and slow-ordering processes appropriately

- Automatically identify high-performing products and prioritize new orders within your logistical systems

- Monitor current inventories against ongoing rates of sale

3. Inventory Replenishment

In volatile markets, knowing when to replenish inventory and in what quantities is a persistent challenge. AI can smooth out some of the more common disruptors.

- Variable, tested hypotheses from historical sales data for improved demand forecasting

- Differentiated in-store and online inventories to match localized shopping preferences

- Adaptive date ranges for replenishing inventory

4. Pricing Intelligence

Using AI, you can incorporate competitor and market pricing data into your inventory management process. For Example, this allows you to identify localized pricing opportunities that match current high-inventory products and push those products through specific channels to reach the right customers.

Proactive, Predictive, Prescriptive and Measurable with Hypersonix

Hypersonix applies end-to-end AI-powered profit optimization analyses to business data, generating real-time, actionable recommendations you can implement every day. With solutions for demand, forecasting, autonomous inventory, and pricing intelligence, Hypersonix can guide your business through turbulent times and keep you on the path to success.

To learn more and request a demo, visit Hypersonix today.