How Hypersonix’s AI Software for Retail Transformed Pricing and Inventory for an Automotive Parts Retailer

THE RESULTS

With Hypersonix AI, our teams spend less time debating numbers and more time acting on them. Pricing is more consistent, inventory is tighter, and the business is finally aligned on where profit really comes from.

— Chief Commercial Officer,

Automotive Aftermarket Retailer

The Background

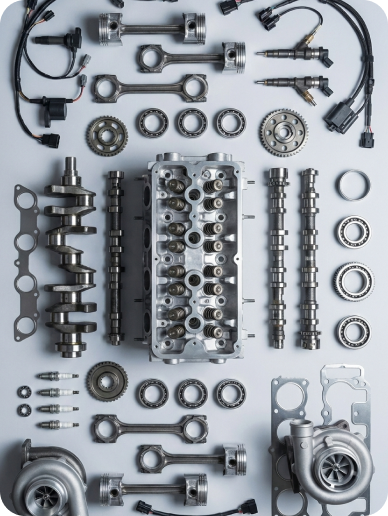

As a national automotive parts and accessories retailer serving DIY drivers, garages and fleets, the company managed tens of thousands of SKUs across batteries, brakes, filters, oil and seasonal accessories. Frequent cost changes, strong seasonality and online price pressure made manual pricing and inventory decisions slow and inconsistent. The team needed Hypersonix’s Pricing AI and Inventory AI to standardize decisions, protect margins and keep stock moving across stores and ecommerce.

Industry: Automotive Aftermarket & Parts Retail

Product Implemented: Pricing AI, Inventory AI

Goal: Automate pricing decisions and optimize inventory to improve margins.

Pricing and Stock Imbalances in a Competitive Market

- Frequent manufacturer cost changes made manual price updates slow and error prone.

- Online and marketplace competitors undercut prices on high visibility SKUs.

- Seasonal peaks in batteries, wipers and winter accessories created stock imbalances.

- Overstock in long tail SKUs tied up working capital and warehouse space.

AI Driven Pricing & Inventory Optimization

Pricing AI

- Served as central pricing software, giving SKU level price recommendations based on cost, demand and margin targets.

- Used elasticity models to flag where to raise prices and where sharper price points were needed to stay competitive.

- Standardized pricing across stores and ecommerce, reducing ad-hoc decisions and price drift.

Inventory AI

- Identified excess stock and at-risk SKUs, guiding markdown priorities instead of blanket discounts.

- Recommended replenishment levels for fast movers based on demand patterns and seasonality.

- Helped rebalance inventory across locations to reduce stockouts in high demand areas and surplus elsewhere.

The Results

+4.7% margin lift in focus categories like brakes, batteries and filters

+4.7% margin lift in focus categories like brakes, batteries and filters

18% improvement in inventory turns on targeted assortments

18% improvement in inventory turns on targeted assortments

15% reduction in aged and slow-moving stock

15% reduction in aged and slow-moving stock

The Hypersonix Impact

- Pricing moved from spreadsheet driven to guided and automated for thousands of SKUs.

- Inventory decisions focused on the SKUs that mattered most for profit and availability.

- The business achieved healthier margins and cleaner shelves while reacting faster to cost and demand changes.

Download the Case Study

Get a copy of the full Case Study PDF, and we’ll send it directly to your email.

Related Resources:

Driving Margin Resilience and Promotional Agility for a Leading Fortune 500 Electronics Retailer with Hypersonix AI Solutions

Driving Margin Resilience and Promotional Agility for a Leading Fortune 500 Electronics Retailer with Hypersonix AI Solutions

Driving Margin Growth & Smarter Promotions for a Fortune 100 Furniture Retailer with Hypersonix AI Solutions

Driving Margin Growth & Smarter Promotions for a Fortune 100 Furniture Retailer with Hypersonix AI Solutions

Driving Margin Growth & Faster Sell-Through with Hypersonix AI for a Top 50 US Sporting Brand in North America

Driving Margin Growth & Faster Sell-Through with Hypersonix AI for a Top 50 US Sporting Brand in North America