How Can Inventory Forecasting Revolutionize Your Retail Strategy?

How Can Inventory Forecasting Revolutionize Your Retail Strategy?

What if you could peer into the future and know exactly what products your customers will want? Inventory forecasting makes this possible.

By leveraging advanced data and analytics, you can predict demand with remarkable accuracy. This not only ensures your shelves are perfectly stocked, but also transforms your entire retail strategy.

From reducing excess inventory to enhancing customer satisfaction, the benefits are immense. In this article, we uncover how inventory forecasting can revolutionize the way you do business, keeping you one step ahead in the retail game.

Quick Takeaways

- Inventory forecasting helps retailers maintain the right amount of stock at all times, preventing overstocking and stockouts.

- Accurate demand forecasting ensures popular products are always available, boosting customer satisfaction and loyalty.

- Effective forecasting reduces costs associated with excess inventory, such as warehousing and insurance, and minimizes the need for rush orders.

- Accurate forecasts lead to more predictable and timely orders, enhancing relationships with suppliers and improving supply chain reliability.

Understanding Inventory Forecasting

Inventory forecasting is the process of predicting future inventory needs using historical data, market trends, and other relevant factors.

This practice helps retailers maintain optimal stock levels, ensuring that they have enough products to meet customer demand without overstocking. Accurate inventory forecasting can significantly improve operational efficiency and customer satisfaction.

Types of Inventory Forecasting

Qualitative Forecasting:

- Relies on expert judgment and market research.

- Useful for new products or startups without historical data.

- Incorporates customer feedback, focus groups, and market intelligence.

Quantitative Forecasting:

- Utilizes historical sales data to predict future demand.

- Best for established businesses with ample past data.

- Methods include time series analysis and regression analysis.

Trend Forecasting:

- Analyzes historical data to identify patterns and predict future demand.

- Factors in seasonality, market trends, and consumer behavior.

- Helps in understanding long-term changes in demand.

Graphical Forecasting:

- Uses visual representations of data to identify trends.

- Makes it easier to spot patterns and relationships between variables.

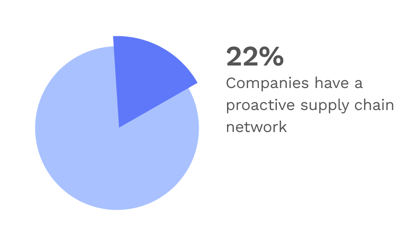

A recent study highlights that only 22% of businesses have a proactive supply chain network, emphasizing the importance of accurate inventory forecasting to stay competitive.

By leveraging advanced analytics and data-driven approaches, inventory forecasting helps retailers navigate market fluctuations and meet customer demands effectively.

The Impact of Inventory Forecasting on Retail Strategy

Inventory forecasting plays a crucial role in shaping an effective retail strategy. It goes beyond merely predicting future stock needs; it transforms various aspects of retail operations, from cost management to customer satisfaction.

Optimizing Stock Levels

Accurate inventory forecasting ensures that retailers maintain the right amount of stock at all times. This balance prevents both overstocking, which ties up capital and incurs storage costs, and stockouts, which can lead to lost sales and dissatisfied customers.

By optimizing stock levels, retailers can significantly enhance their financial performance. According to a recent report, 82% of businesses cannot quantify an ROI on their inventory management systems, yet they still invest in them due to the substantial benefits of maintaining optimal inventory levels.

Enhancing Customer Satisfaction

When retailers accurately forecast demand, they can ensure that popular products are always available. This availability boosts customer satisfaction and loyalty, as shoppers are more likely to return to a store that consistently meets their needs. Maintaining the right inventory levels can minimize stockouts, directly contributing to a better customer experience and repeat business.

Reducing Costs

Effective inventory forecasting helps retailers reduce costs associated with holding and managing excess inventory.

By predicting demand accurately, businesses can avoid overordering, thus saving on:

- Warehousing

- Insurance

- Deterioration costs

Additionally, precise forecasting reduces the need for expensive rush orders and emergency shipments, further cutting operational expenses.

Improving Supplier Relationships

Good inventory forecasting can enhance relationships with suppliers. By providing accurate forecasts, retailers can plan orders better, leading to more predictable and timely deliveries. This predictability strengthens supplier partnerships, which are crucial for negotiating better terms and ensuring a reliable supply chain.

Enabling Strategic Decision-Making

Inventory forecasting provides valuable insights that aid strategic decision-making. Retailers can use forecast data to plan promotions, manage product assortments, and make informed decisions about market expansions.

This strategic use of data ensures that businesses remain agile and responsive to market changes, helping them stay competitive.

Integrating Inventory Forecasting with Retail Strategy

Integrating inventory forecasting into your retail strategy requires a comprehensive approach that aligns various aspects of your business operations. Here’s how to do it effectively:

Aligning Forecasting with Sales and Marketing

To optimize your inventory levels, it’s crucial to align your forecasting efforts with your sales and marketing strategies. By integrating data from sales trends, marketing campaigns, and customer behavior, you can create more accurate demand forecasts.

For instance, understanding the impact of upcoming promotions and sales events allows you to adjust inventory levels accordingly. This alignment ensures that you have enough stock to meet promotional demand without overstocking.

Leveraging Technology for Better Forecasting

Advanced analytics and machine learning models are essential tools in modern inventory forecasting. These technologies help analyze vast amounts of data to identify patterns and predict future demand more accurately.

For example, machine learning algorithms can consider various factors such as market trends, historical sales data, and external variables like economic conditions and seasonal fluctuations. Implementing these technologies can significantly enhance the precision of your forecasts, helping you maintain optimal inventory levels and reduce costs.

Adapting to Market Trends and Seasonality

Market trends and seasonality play a significant role in inventory forecasting. By closely monitoring these trends, retailers can anticipate changes in demand and adjust their inventory levels accordingly.

For example, trend forecasting involves analyzing sales data to identify broader shifts in consumer behavior beyond seasonal variations, such as viral product popularity or demographic changes. Understanding these trends allows retailers to stay ahead of the curve and make informed inventory decisions.

Collaborative Approach

Effective inventory forecasting requires collaboration across different departments within your organization. Sales teams can provide valuable insights from their direct interactions with customers, while marketing teams can share information about upcoming campaigns. Procurement teams can offer details about supply chain dynamics and lead times.

By fostering a collaborative environment, you ensure that your forecasting models are enriched with diverse perspectives, leading to more accurate and reliable predictions.

Implementing Demand-Driven Replenishment

Demand-driven replenishment is a strategy that aligns inventory restocking with actual market demand based on customer data and sales trends. This approach helps minimize the risks of stockouts and overstock situations by ensuring that inventory levels are closely aligned with current and forecasted demand.

Advanced analytics tools are essential for assessing sales trends and customer preferences, allowing for precise and responsive inventory management.

Continuous Monitoring and Adjustments

The retail landscape is dynamic, and inventory needs can change rapidly. Continuous monitoring of your forecasting models and making real-time adjustments are critical to maintaining optimal inventory levels.

This involves regularly updating your data, reviewing forecast accuracy, and responding promptly to new insights or changes in market conditions. Such proactive management ensures that your inventory strategy remains agile and effective.

Achieve Agility and Efficiency Today with Hypersonix

Inventory forecasting is a powerful tool that can revolutionize your retail strategy by optimizing stock levels, reducing costs, and enhancing customer satisfaction. By integrating advanced analytics and fostering collaboration across departments, retailers can create accurate demand forecasts and adapt to market trends effectively.

Hypersonix ensures effective inventory forecasting by leveraging advanced analytics and AI-driven models to analyze vast amounts of data, identifying patterns in:

- Market trends

- Historical sales

- External factors

Our technologies enable precise demand predictions, helping retailers maintain optimal stock levels and reduce costs associated with overstocking and stockouts. By integrating real-time data and fostering cross-departmental collaboration, Hypersonix provides actionable insights that enhance overall inventory management and operational efficiency. Read more about ProfitGPT.

Learn how Hypersonix’s solutions can transform your retail business and drive success. Book a demo today to start achieving agility and efficiency!