How to Keep Your Ecommerce Supply Chain Strong

How to Keep Your Ecommerce Supply Chain Strong

In 2022, 80% of consumer-facing businesses reported experiencing one or more major supply chain disruptions, with 50% reporting three or more. Looking forward, 61% of surveyed logistics managers do not expect supply chain conditions to normalize in 2023 or 2024. As economic and geopolitical uncertainties continue to loom over global commerce, industry leaders must act to keep their ecommerce supply chains strong and continue to develop reliable, transparent supplier relationships.

Global supply chains are complex networks of highly variable localized conditions with limited top-down visibility for any single participating organization. In a globalized digital economy, businesses often have as little understanding of where the products they buy and sell come from as consumers.

In this guide, you’ll learn what the ecommerce supply chain is and how you can stabilize it for your business.

Key Takeaways

- Supply chain disruptions and vulnerabilities in ecommerce will likely continue throughout 2023.

- The ecommerce supply chain is the series of organizations and processes that materials and products pass through to reach end consumers.

- Ecommerce businesses can maintain a strong supply chain by developing supplier relationships, optimizing fulfillment processes, and leveraging automation technologies.

What Is the Ecommerce Supply Chain?

The ecommerce supply chain consists of the business and logistics processes involved in supplying products available to consumers through ecommerce businesses. The supply chain includes the following components:

- Raw material suppliers

- Manufacturers

- Mid-tier assemblers

- Shipping services

- Warehousing and inventory management services

- Fulfillment services

Depending on size and product offerings, ecommerce businesses may own or contract any part of their supply chain infrastructure and services. However, most ecommerce businesses rely on third-party providers for major stages of production or distribution.

4 Ways to Strengthen Your Ecommerce Supply Chain

Here are four ways ecommerce companies can maintain a strong supply chain.

1. Build Supplier Relationships

During the pandemic, many ecommerce businesses and their supply chain partners experienced material scarcity for the first time. Suppliers and service providers often had to choose which standing obligations to fill and which to postpone. While the immediate impact of supply-side scarcity was raised prices, suppliers must consider the long-term value of their relationships.

A one-off buyer with more cash on hand today may not be a wiser business choice than a trusted partner with a reliable track record and a commitment to future business.

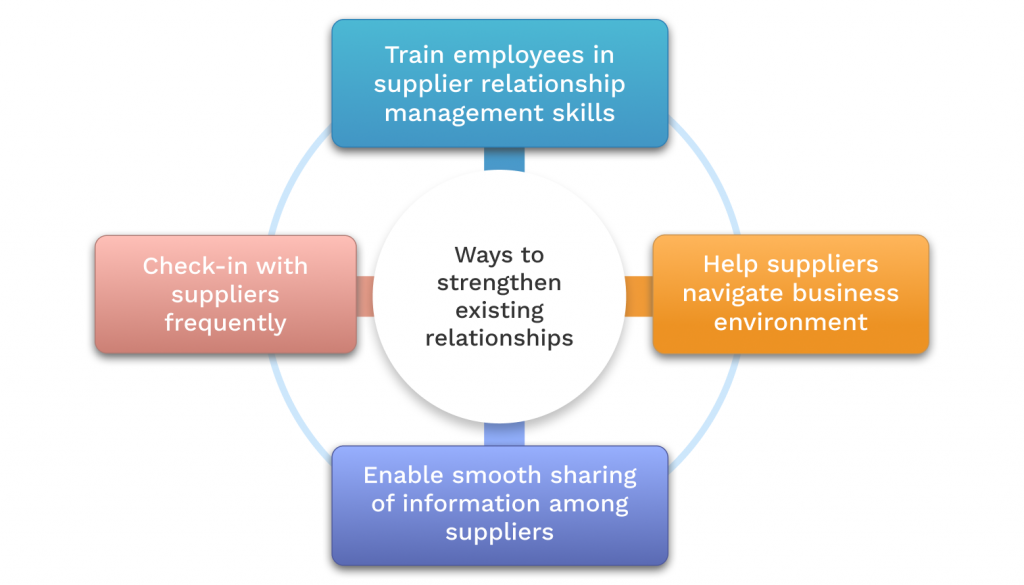

Supplier relationship management may seem dated from a pre-globalized and predigital era. However, ongoing uncertainties have returned significant value to the practice. Deloitte Insights identifies four components for solidifying supplier relationships:

- Employee training in supplier relationship management skills

- Removal of barriers to information sharing

- Buyer-side assistance to suppliers

- Regular check-ins with supplier decision-makers

2. Leverage Automation in Fulfillment

Ecommerce customers have dwindling patience for slow delivery times and delays. According to data from Voxware’s 2022 Holiday Survey, consumers are often disappointed with ecommerce delivery and have higher expectations of what routine delivery should be. Among online shoppers:

- Worrying that holiday and seasonal purchases will arrive on time is a purchase-influencing decision 61% of the time.

- After two to three late deliveries, 65% will switch brands or retailers – for incorrect orders, that percentage rises to 81%.

- With items in a cart and ready to purchase, 38% will abandon their carts if estimated delivery times exceed seven days, compared to just 16% for six to seven days.

Ecommerce companies that rely on manual labor for order fulfillment and inventory management will struggle to keep up with consumer expectations for timely delivery. For most, the only viable path for achieving competitive fulfillment standards at scale is implementing automation in warehouses and fulfillment centers.

While owned, automated infrastructure is beyond the budget of many small-to-medium-sized businesses, they can use third-party logistics services and invest in ongoing workforce training for in-house operations.

3. Choose the Right Order-Picking Strategy

In retail and ecommerce, order picking refers to the process of efficiently moving products from storage spaces to shipping stages. Different order-picking strategies suit operations of different sizes and product types. Factors that influence order-picking performance include:

- Average product weight and physical dimensions

- Rate of single line-item orders

- Availability of flex labor

- Facility layouts

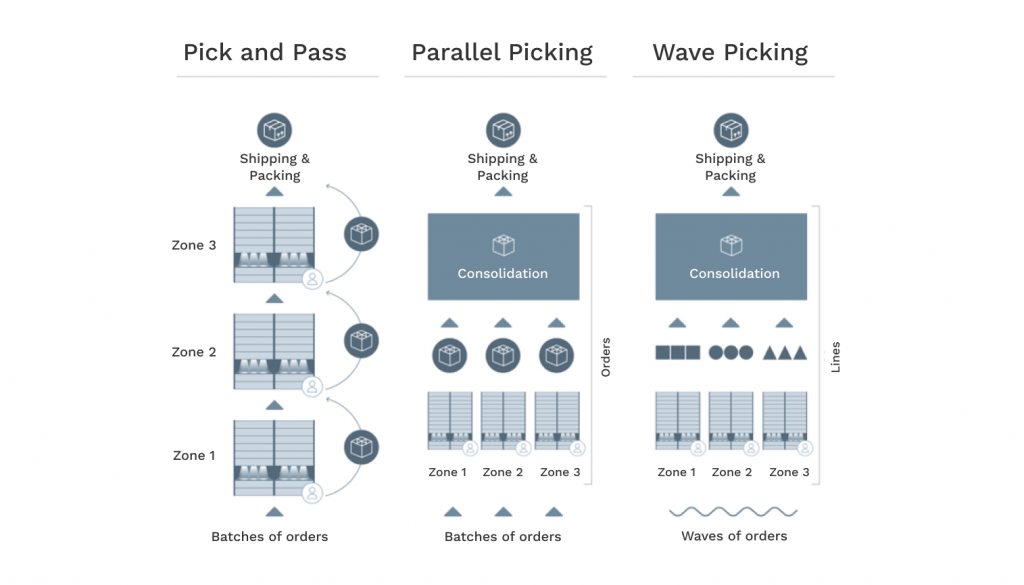

With multiple variations for each, there are three effective order-picking strategies ecommerce companies currently use:

- Pick and Pass: Consists of picking order items from different warehouse zones successively until the order is complete. With order management and inventory intelligence software, pick and pass can route item collections efficiently past zones with no ordered products. Using this strategy, orders arrive complete for shipping without any repackaging needs.

- Parallel Picking: Assigns warehouse workers or automation equipment to specific warehouse zones and routes orders completed for each zone down parallel rows. In this arrangement, no workers or machines pass between zones, and orders await final packing in a consolidation zone. Parallel picking allows fulfillment centers to process many orders simultaneously.

- Wave Picking: Sends workers and machinery in repeated waves through tracks of zones. Each picking unit passes through the same zones every wave and pauses only to collect outstanding items for that wave. Wave picking greatly reduces sorting operations in consolidation zones.

4. Supply and Demand Forecasting with Artificial Intelligence (AI)

Combining a business’s historical sales data with economic trend data, global and regional fuel costs, and average times to destination along relevant shipping lanes can reveal patterns that can guide decision-making and advanced planning. With sufficient predictive analytics, businesses can identify supply chain vulnerabilities and price fluctuations before feeling the brunt of their effects.

However, the depth of analysis and the volume of data involved in reliable supply chain forecasting are beyond the reach of most organizations using manual spreadsheet analysis. To monitor the necessary data sources continuously and detect patterns with sophisticated algorithms, most organizations need AI-enabled software platforms.

AI-Enabled Predictive and Prescriptive Ecommerce Recommendations with Hypersonix

Hypersonix’s AI platform for retail and ecommerce businesses collects and analyzes diverse data sources within your business and externally in the market to provide tailored, actionable recommendations for decision-makers.

With capabilities for supply and demand forecasting, inventory optimization, and dynamic pricing, Hypersonix translates raw business data into improved profits and performance.

Schedule a personalized demo today.