Back to business: How data intelligence helps supply chain recovery

Back to business: How data intelligence helps supply chain recovery

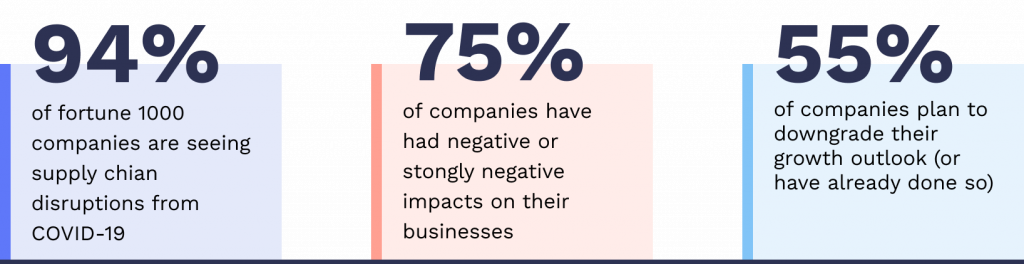

Two years on, the COVID-19 pandemic continues to disrupt lives, economies, and businesses. With new variants popping up, countries are reimposing lockdowns and border restrictions. While different countries are in various stages of recovery, the supply and demand issues are all over the place – significantly affecting global trades and their routes.

Pre-pandemic, the global supply chain followed a top-down or large supplier to small supplier hierarchy. But during the pandemic, the unplanned shutdown of small manufacturers and suppliers set off a butterfly effect that continues to disrupt global trade. Temporary ‘manufacturing deserts’ forced businesses to reassess their supply chain management. For instance, when HP was forced to shut its factories in China and Southeast Asia, it quickly ran out of critical components (computer panels and central processing units) for its line of products. The transportation disruption has further led to the rise in prices of raw materials, hindrance in shipping and road freights, interruptions in goods flow, and for many industries a complete shutdown of operations, sales, and international trade.

NASA also released an image depicting the effect of supply chain crunch – a staggering 14 by 16 miles of the sea with over 70 ships waiting to dock and unload at the Los Angeles and Long Beach ports.

The strained supply chains and geopolitical tensions have also negatively impacted consumers. From rising commodities costs to shipping delays, uncertainties across all supply chain stages have changed the way consumers shop and stock products. As a result, product shortages are reported worldwide ranging from paper products to toys for the upcoming holiday season. The continuous delays and logistical hiccups mean businesses are losing a significant portion of valuable consumers. According to a study by Oracle, 80 percent of consumers say that delays or product shortages would force them to stop buying from their favorite brands.

Overcoming supply chain disruptions

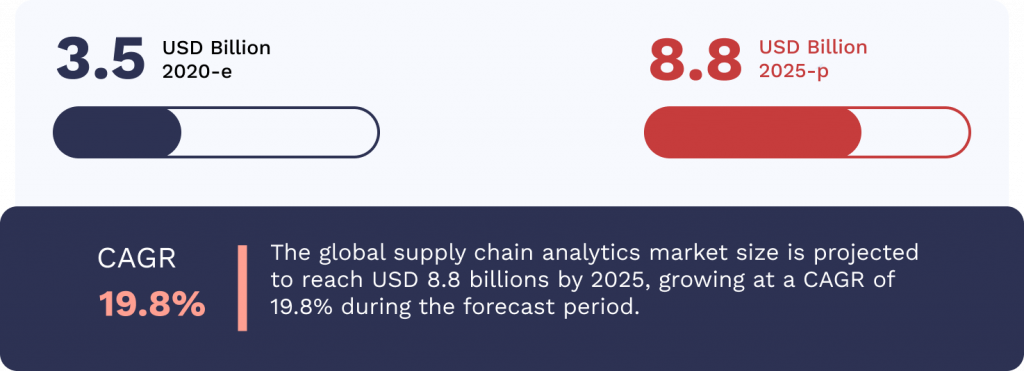

Over the last decade, technology has transformed supply chain management and process. From automating tasks to increasing visibility of processes, technology has helped bring in the age of smart supply chain and logistics. Unfortunately, with this technology comes a vast amount of data – most of it sitting idle in data centers.

The one thing that global supply chains require to succeed is efficiency. But without the right actionable insights, companies are in the dark on how the complex web of logistics, products, procurement, and marketing all fit together.

This is where artificial intelligence (AI) helps by filtering through the noise, finding patterns, and providing actionable insights for organizations. For example, Oracle’s survey notes that 76 percent of respondents “would be more willing to buy from a brand they knew used AI to manage their supply chain.”

AI and data intelligence forms the backbone of today’s digital supply chain technology. When done right, data intelligence is a shot-in-the-arm for a swift supply chain recovery. It helps organizations build an intelligent global supply chain to solve dynamic issues such as:

- Preventing losses with prescriptive analytics

- End-to-end supply chain visibility

- Reducing costs with better forecasting and monitoring

- Optimizing inventory with AI

For instance, when Nike had to shut its Asian markets, their supply chain disruption significantly impacted the cost of production and distribution. The sporting giant had to decrease its reliance on third-party manufacturers and logistics operations and focus on placing its products closer to the consumer. Nike was able to fix its crumbling supply chain with early IT investments in data analytics, automation, and near-shoring/ micro-warehousing their products with trusted distribution partners. A whirlwind online retail strategy coupled with smart forecasting and inventory management fortified Nike sales. It overcame the need to export large quantities and optimize its inventory to serve its customers with eCommerce fulfillment centers.

Kroger attributes its recent increase in its guidance for fiscal 21 to its ability to use data and personalization to enable customers to stretch their dollars while introducing many interventions to expand growth. Kroger sharpened its private-label offerings, thereby reducing dependency on the global supply chains.

And needless to say, Amazon’s leadership in supply chain innovations has been a stellar reference of how nothing can be challenging with the right data and technology.

As more and more enterprises understand the importance of AI and data intelligence, we see an increase in technology investments. However, most enterprises are unable to realize the benefits of their investments. Only a few businesses have succeeded in fully understanding their data and effectively using it. According to Gartner, part of the problem to the success of supply chain analytics is a lack of scalable data foundation, shortage of skilled employees, and lack of clarity on supply chain analytics business.

Bringing in supply chain resilience

According to McKinsey, “supply chain disruptions lasting a month or longer now happen every 3.7 years on average.” COVID-19 may have fractured global supply chains, but it’s interesting to note how it exposed the vulnerabilities of the system. Businesses and consumers alike wanted to understand where and how their products are sourced, manufactured, and distributed.

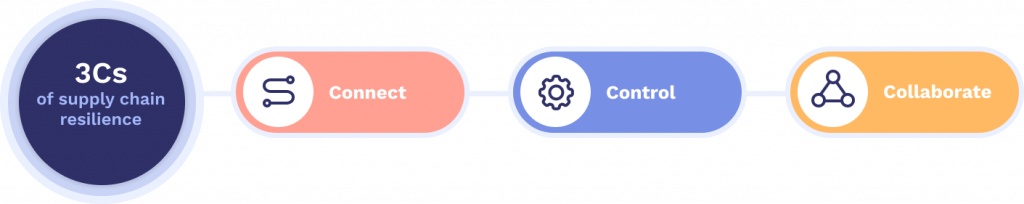

A resilience approach can be built by understanding the 3 Cs of supply chain resilience:

Connect

As you expand your business, your supply chain diversifies to include multiple suppliers, vendors, manufacturers, warehouses, and consumers across continents. Maintaining regular communication between this web of stakeholders is critical to spot anomalies sooner and rectify them.

Collaborate

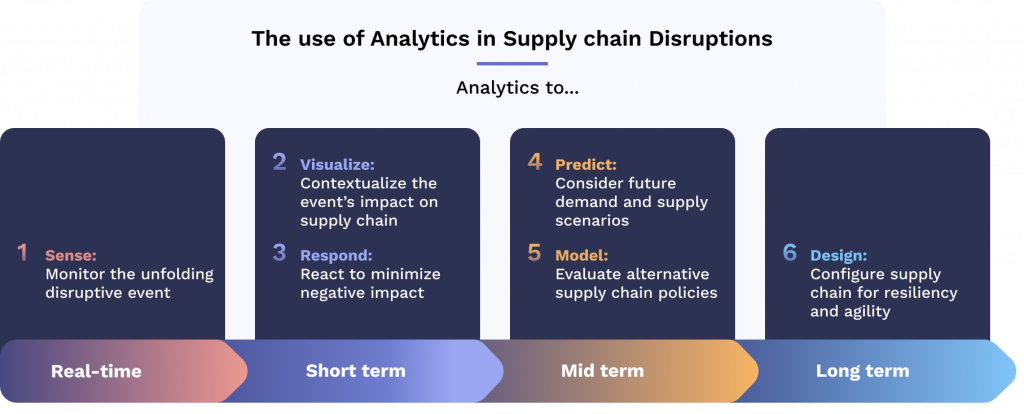

Today’s supply chain is a complex web of automation that demands better collaboration with multiple partners. A collaborative platform helps bring in transparency and increase visibility across business tiers. The continuous information sharing shifts the supply chain dynamics to a ‘sense and respond’ mode of operation – injecting flexibility, visibility, velocity, and sustainability.

Control

AI provides deep insights into the critical dependencies of a supply chain. In addition, the 360-degree view of risk helps establish controls across the supply chain. Data intelligence ties all these components together to deliver an efficient supply chain that is entirely mapped. By creating digital twins, running simulations, and stress testing the supply chains, enterprises are better prepared to quantify the resilience of their supply chain.

By fully embracing the power of AI and data intelligence, supply chain executives can control and manage all dimensions of the supply chain. While the applications of data intelligence are enticing, attaining these goals is a work in progress. Leaders must first understand and accept that the world is truly different. Today’s customer-centric supply chains are not efficiency-driven — rather, they are built to help organizations grow smartly and effectively. The global scale of personalization can only be achieved with better demand sensing, monitoring, and continuous improvement in data segmentation.