AI in Inventory Management: Using to Optimize your Inventory

AI in Inventory Management: Using to Optimize your Inventory

Perhaps Mick Jagger and Keith Richards of the Rolling Stones really were on to something in 1965 when they first sang “I Can’t Get No Satisfaction,” especi

ally considering the lyrics still resonate with audiences some 55 years later.

Over the past five-plus decades, inventory optimization has changed significantly for business-to-consumer (B2C) organizations like retailers, ecommerce enterprises, and hospitality organizations. Consumers now play a more proactive role in expressing their needs and preferences to enterprises.

Even though inventory management software has been around for nearly half a century, businesses continue to struggle to anticipate consumer demand and what to stock accurately. Consumers are still getting no satisfaction, as what they want is often not in stock.

But why is this the case? Businesses now have more timely information, better technology, and more data than ever before. In theory, these advantages should make it easier to avoid overstock or out-of-stock situations. This guide explores why this isn’t necessarily the case and how AI can close the consumer satisfaction gap.

Key Takeaways

- Despite developments in traditional inventory management methods, businesses still struggle to meet consumer expectations for accurate, available inventory.

- The next generation of solutions for inventory optimizations relies on artificial intelligence (AI), machine learning (ML), and data science.

- Hypersonix excels at AI-driven inventory optimization even in a business environment of uncertainty and supply chain disruptions.

Why Are Consumers Feeling a Renewed Sense of Frustration?

The short answer is that ecommerce and digital transformation have permanently transformed consumer behavior. So far, most retailers, ecommerce enterprises, restaurants, and hospitality organizations remain stuck with technologies and processes unfit to weather this transformation.

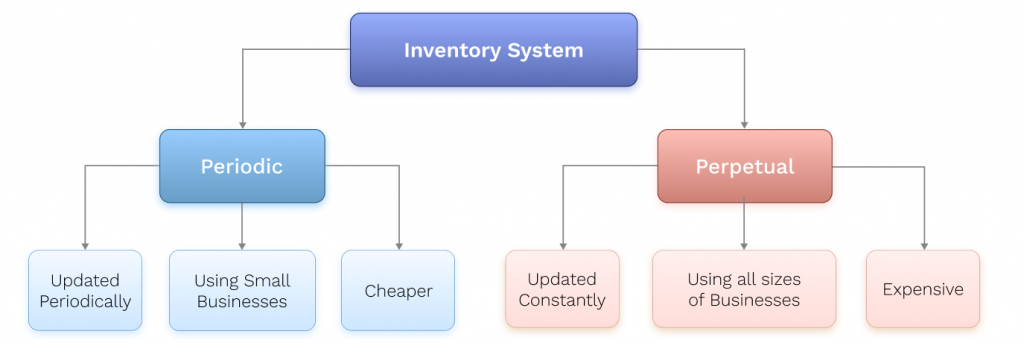

Today’s successful commerce organizations have embraced real-time perpetual inventory management systems that integrate seamlessly with online and in-store transactions. They proactively avoid lost sales attributed to out-of-stock inventory and reduce non-value-adding inventory, which ties up working capital. The winners also have less shrinkage and spoilage of inventory.

However, most legacy inventory management systems still rely on outdated demand forecasting algorithms that lack channel-specificity and the ability to understand online shopper demand patterns. These algorithms are biased toward in-store shopping and result in less accurate predictions for digital channels.

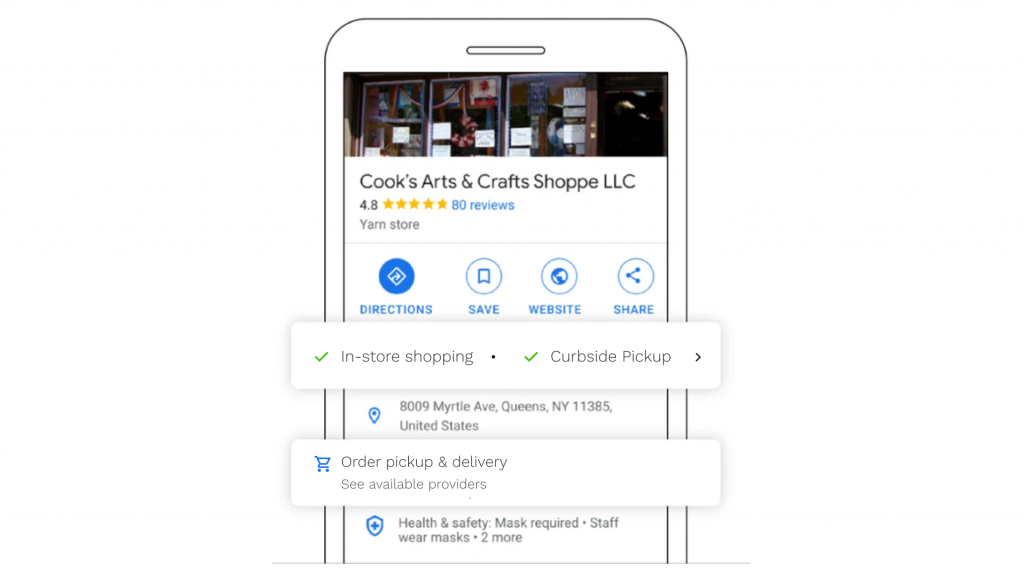

When this occurs, consumers often become frustrated because they end up not receiving all the products they ordered. While stockout rates for retailers and ecommerce businesses typically average around 8%, rates have risen 250% since the COVID-19 pandemic in 2020. At the same time, consumers increasingly want omnichannel shopping options such as online browsing and purchasing with in-store pickup. In the last few years, Google searches tagged with “open now near me” have grown year-over-year by 400%.

Solutions Based on Artificial Intelligence (AI), Machine Learning (ML), and Data Science

What is the remedy for ongoing customer frustration with inventory issues? It starts with developing inventory optimization capabilities through artificial intelligence (AI), machine learning (ML), and data science. Platforms operating on these tools autonomously revolutionize your demand forecasting and inventory, eliminating the problems of stock shortages and overstocking.

Demand forecasting and inventory optimization tools in the current era must be:

- AI-Powered

- Autonomous,

- Real-time,

- Provably accurate

- Channel specific

They must understand both in-store and online demand signals. Forecasts must be accurate by every line item – product, store, date, and time. Demand forecasts must account for the effects of the following:

- Pricing

- Promotions

- Assortment

- Seasonality

- Events

- Holidays

- Weather

With proper autonomous demand forecasting in place, the ideal solution for most companies will be a real-time perpetual inventory that can support available-to-promise commitments for customers and scalable persistent monitoring. Many B2C companies elect not to use a real-time perpetual inventory because their receiving, inventory, and POS scanning practices lack discipline and integrity.

However, AI-powered autonomous inventory solutions should appeal to businesses facing this challenge. Auto-detection and proactive avoidance of inventory scarcity issues resolve potential stockouts faster than manual systems for perpetual inventory.

What Does AI Mean for You?

A sort of AI fatigue and posturing permeates the world of inventory and forecasting across the supply chain industry. Nevertheless, researchers are making great strides in the data science fields of ML and deep learning, helping non-technical decision-makers harness data-driven insights without becoming overly dependent upon IT or in-house data scientists.

AI and other automated data science tools will never replace entirely the strategic expertise and intimate knowledge decision-makers have about their own businesses. But these technologies will enhance their resolve to undertake new initiatives going forward. In other words, AI is not going anywhere, but where specifically it goes within inventory optimization will vary for each business.

How AI Enables Inventory Optimization Today

Presently, AI has a poorly defined, customer-facing role in inventory optimization. There are frustrating chatbots on websites as well as less than satisfying automated emails that inform consumers when an out-of-stock item might become available. AI, ML, and other data science models in these roles will likely continue to be problematic and insufficient for the time being.

Business-Facing AI Applications

For business-facing applications, AI tends to remain underdeveloped. Despite the many inventory optimization solutions available, demand planning and forecasting platforms at even the world’s largest retail chains still cannot answer the simple question, “How much inventory should be on hand on any day and at any one time?”

AI, ML, and other data science models can make sense of reams of data from legacy and disparate inventory management systems, integrating data on historic consumer buying patterns through cloud applications. In other words, these technologies can provide answers to the inventory question by aggregating and analyzing consumer demand, supplier orders, production orders, re-order points, and economic order quantities.

Compliance Standards and Inventory Optimization

To achieve effective inventory management and prevent stockouts, businesses require more than smart machines and historical data. They must understand why certain processes exist in the first place to effectively minimize the risk of out-of-stock situations as well as prevent safety stock from becoming deadwood. Operating with sufficiently customized compliance standards, an inventory optimization platform can help inventory planners anticipate both how much to order and when.

AI in inventory optimization can aid businesses in the transition from instinctive, manual practices to data-backed processes. Nevertheless, AI is not a cure-all for poor company practices or outdated inventory management systems. Rather, it assists businesses in identifying which existing inventory methods cause unreliable inventory levels and optimizing their inventory processes.

The Importance of Simulation

The most critical of these methods is historical data simulation. Even though AI cannot predict future outcomes with 100% certainty, a robust and intelligent platform can run far more combinations in simulation than any statistician and calculate a near-infinite number of permutations.

This deeper level of data insight guides planners and schedulers to identify items at risk of a stockout. Once a probability is known, decision-makers can identify an appropriate amount of safety stock to have on hand and prepare accordingly.

COVID-19 Impact and Lasting Supply Chain Effects

The global supply chain continues to reel from the impact of COVID-19 restrictions on economic activity. Even when these effects ultimately subside, businesses need to remember the lessons they have learned about the permanence of uncertainty.

However, going forward, AI is an example of a new and still developing capability for businesses to mitigate the risks of unexpected disruptions. While the pandemic threw businesses a curveball, AI, ML, and data science can react to today’s challenges with enhanced anomaly detection and greater forecasting accuracy.

AI-Driven Inventory Optimization with Hypersonix

In an environment of increased uncertainty and ongoing operational disruptions, AI-powered solutions like inventory optimization can reduce inventory shortages and customer frustration while freeing decision-makers from a cycle of minimally effective spreadsheet analysis.

Hypersonix Profit OS provides advanced AI capabilities for inventory and profit optimization to retailers and ecommerce enterprises. With real-time monitoring for a comprehensive range of variables and vast continuous simulative abilities, Hypersonix streamlines day-to-day operations and shields businesses against unexpected disruptions. Read about inventory AI

Get a personalized demo of Hypersonix Profit OS today.